TJ-HB160/SP-KB3000/SP Large hollow blow molding machine

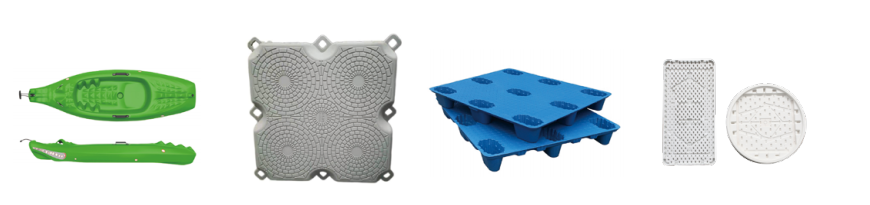

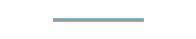

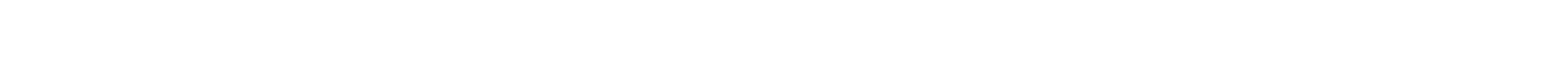

Tongjia TJ-HB160/SP-KB3000/SP series large-scale hollow blow molding machines are mainly designed and developed for special-shaped hollow parts. Features. The products used in the production include automobile air ducts, fuel tanks, urea tanks for vehicles, plastic water horses, anti-collision buckets, pole anti-collision buckets, fences and other transportation facilities, water surface floating balls, sea surface floating buckets, environmental protection floating islands and other plastics Floating bodies, various panels, various fences, etc.

Add to quote| Mold opening and closing system: Diagonal double tie rod center mold locking bidirectional synchronous high-precision linear guide rail guide mold opening and closing mechanism |

| Die head: single cylinder center feed accumulator type die head |

| Extrusion system: variable frequency speed regulation + hard tooth surface reducer |

| Hydraulic system: all imported hydraulic valves + hydraulic servo control system |

| Control system: imported PLC+ European imported complete machine control system (Jeffren, Italy) |

| 1 Specifications | Units | TJ-HB160SP | TJ-KB1000SP3 | TJ-KB1000SP6 | TJ-KB1500SP | TJ-KB2000SP | TJ-KB3000SP2 |

| 1.1 Material | HDPE | HDPE | HDPE | HDPE | HDPE | HDPE | |

| 1.2 Die quantity | Set | 1 | 1 | 1 | 1 | 1 | 1 |

| 1.3 Machine dimension | M | 6.8×4.0×5.0 | 9.1×5.6×6.3 | 9.1×5.6×6.3 | 9.1×5.6×6.3 | 10.6×7.1×8.0 | 10.6×7.1×8.0 |

| 1.4 Machine weight | Ton | 23 | 35 | 42 | 45 | 48 | 48 |

| 2 Die-head | |||||||

| 2.1 Accumulator capacity | L | 12.8/20/30 | 30 | 40 | 30/40 | 50/60 | 50/60 |

| 2.2 Max.Diameter of die | mm | 400/500/650 | 650 | 750 | 650/750 | 750/860 | 750/860 |

| 2.3 Die head heating power | KW | ≈33/45/54 | 54 | ≈58 | ≈54/58 | ≈60/64 | ≈60/64 |

| 2.4 Die head heating zone quantity | zone | 3/4/5 | 5 | 5 | 5 | 6 | 6 |

| 3 Clamping Unit | |||||||

| 3.1 Clamping force | KN | 660 | 1000 | 1000 | 1300 | 2400 | 2400 |

| 3.2 Distance between platens | mm | 700-1500 | 900-2200 | 900-2200 | 600-2100 | 700-2200 | 700-2200 |

| 3.3 Mold platen size(W×H) | mm | 1100×1400 | 1400×1600 | 1400×1900 | 1400×1750 | 1400×2800 | 1400×3200 |

| 4 Extruder unit | |||||||

| 4.1 Screw diameter | mm | 100 | 75 | 120 | 120 | 135 | 135 |

| 4.2 Screw L/D ratio | L/D | 25 | 33 | 25 | 25/30 | 32 | 32 |

| 4.3 Plasticizing amount | Kg/h | 200(HDPE) | 240(HMWHDPE) | 280(HDPE) | 280/380(HMWHDPE) | 420(HMWHDPE) | 420(HMWHDPE) |

| 4.4 Screw heating zone quantity | zone | 5 | 5 | 6 | 6 | 6 | 6 |

| 4.5 Screw heating power | KW | 23 | 23 | 33 | 33/36 | 48 | 48 |

| 4.6 Extruder driving power | KW | 75 | 90 | 110 | 110/132 | 160 | 160 |

| 5 Power | |||||||

| 5.1 Total power consumption | KW | 168/180/189 | 250 | 254 | 250/279 | 321/325 | 321/325 |

| 5.2 Hydraulic drive power | KW | 37 | 45+7.5 | 45+7.5 | 45+7.5 | 45+7.5 | 45+7.5 |

| 5.3 Cooling water consumption | m³/h | 18 | 30 | 30 | 35 | 40 | 40 |

| 5.4 Cooling water pressure | Mpa | 0.3-0.6 | 0.3-0.6 | 0.3-0.6 | 0.3-0.6 | 0.3-0.6 | 0.3-0.6 |

| 5.5 Air pressure | Mpa | 0.8 | 1 | 1 | 1 | 1 | 1 |

| 5.6 Air consumption | m³/min | 1.6 | 2 | 2 | 2.5 | 3 | 3 |